Understanding the basics of a 2 Wire Rtd Wiring Diagram is essential for anyone working with temperature measurement systems. This diagram provides a straightforward representation of how a two-wire Resistance Temperature Detector (RTD) connects to a measuring instrument, offering a reliable and cost-effective solution for many applications.

Understanding the 2 Wire Rtd Wiring Diagram

A 2 Wire Rtd Wiring Diagram illustrates the simplest configuration for connecting an RTD sensor. Unlike more complex three or four-wire setups, the two-wire system uses the same pair of wires to both energize the RTD element and carry the resistance signal back to the measuring device. This makes installation straightforward and reduces the number of conductors required. The RTD itself is a temperature-sensitive resistor, meaning its electrical resistance changes predictably with variations in temperature. This change in resistance is what allows the connected instrument to infer the current temperature at the sensor's location. The simplicity of the 2 Wire Rtd Wiring Diagram is its primary advantage for basic temperature monitoring.

In a typical 2 Wire Rtd Wiring Diagram, you'll see the RTD sensor with two terminals. These terminals are then connected directly to the input terminals of a temperature controller, indicator, or data acquisition system. The measuring instrument applies a small, constant current through the RTD. As the temperature changes, the resistance of the RTD also changes. The instrument then measures the voltage drop across the RTD. By knowing the relationship between the RTD's resistance and temperature (often a standard curve like that for Pt100), the instrument can accurately calculate and display the temperature. Here are some common RTD types:

- Pt100

- Pt1000

- Nickel (Ni100, Ni120)

While the two-wire configuration is simple and economical, it's important to be aware of its limitations. The resistance of the connecting wires themselves can introduce an error into the measurement, especially over longer distances or with smaller RTD resistance values. This is because the instrument measures the total resistance of the RTD element plus the resistance of the two wires. For applications requiring high accuracy, especially where the cable length is significant, a three or four-wire RTD setup is generally preferred to compensate for lead wire resistance. However, for many general-purpose temperature sensing needs, the 2 Wire Rtd Wiring Diagram offers a perfectly acceptable and practical solution. The wiring process typically involves:

- Identifying the two terminals on the RTD.

- Connecting one terminal to the positive input of the measuring device.

- Connecting the other terminal to the negative input of the measuring device.

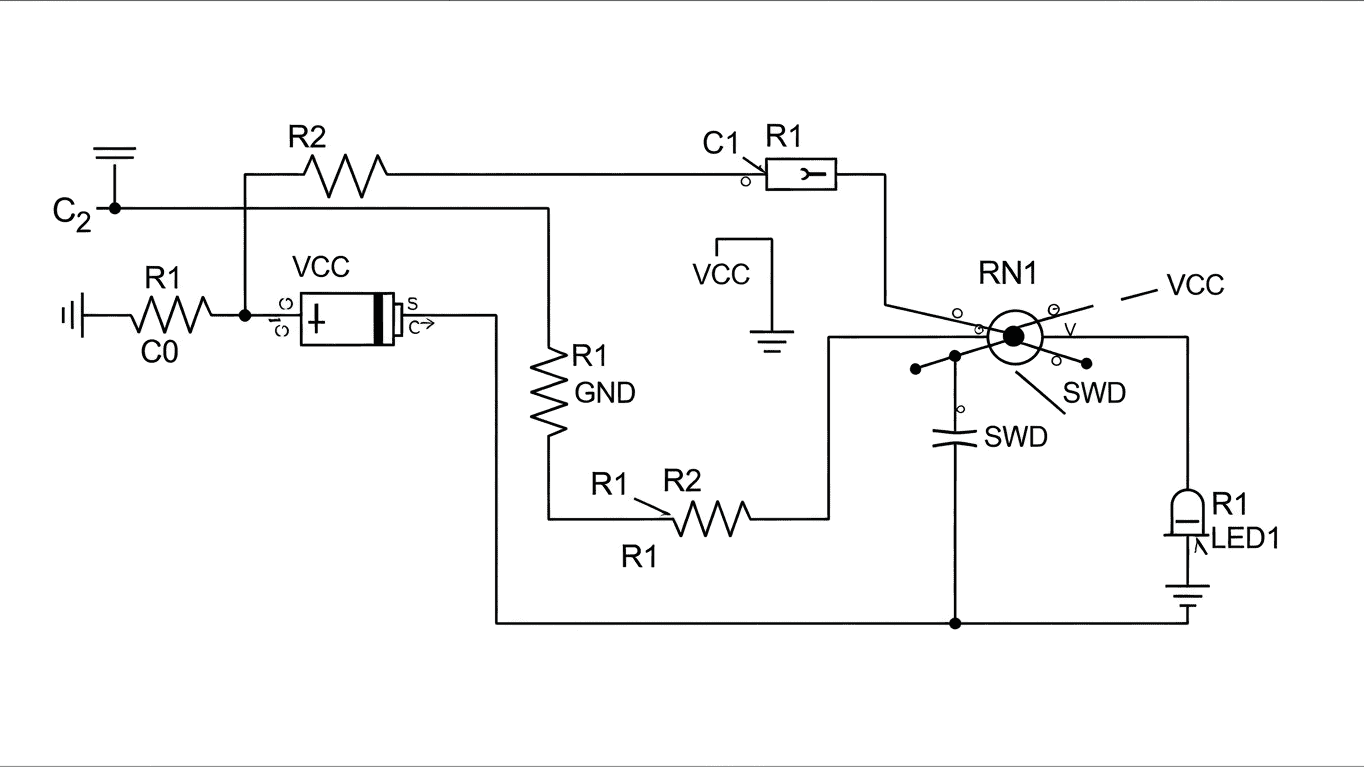

Here's a simplified representation of the connection:

| RTD Terminal 1 | Measuring Device Terminal + |

|---|---|

| RTD Terminal 2 | Measuring Device Terminal - |

For a clear visual guide and to ensure you have the correct understanding for your specific setup, please refer to the detailed diagrams and explanations provided in the next section.