Delving into the world of industrial automation and process control often leads us to the critical components that enable precise measurement. Among these, the 2 Wire Pressure Transmitter Wiring Diagram stands out as a foundational concept for many applications. Understanding this diagram is not just about connecting wires; it's about grasping how crucial pressure data is reliably transmitted to control systems.

The Essentials of a 2 Wire Pressure Transmitter Wiring Diagram

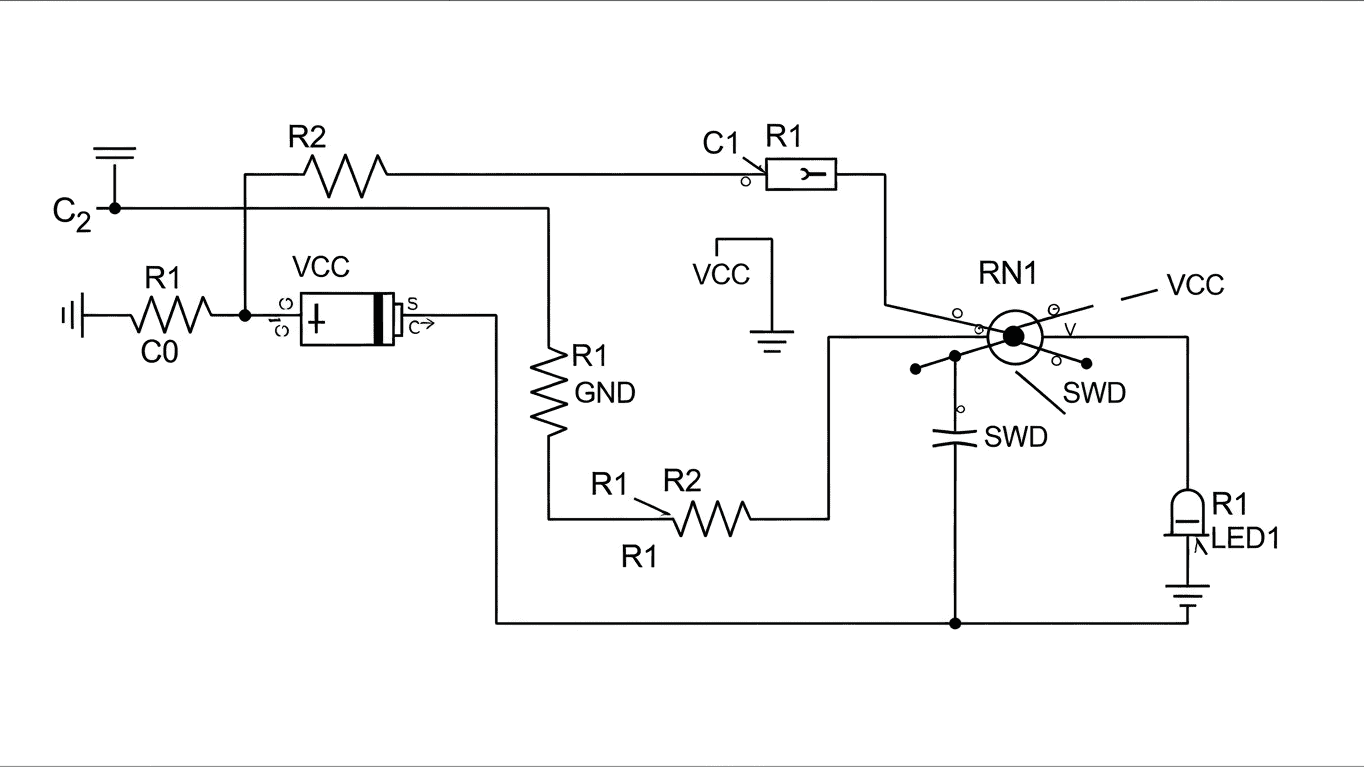

A 2 Wire Pressure Transmitter Wiring Diagram is a schematic that illustrates the simplest and most common method for connecting a pressure transmitter to a power source and a receiving device, typically a control system or indicator. Unlike older, multi-wire designs, the two-wire transmitter utilizes a single pair of wires to both supply power to the transmitter and carry the processed pressure signal. This elegant design significantly reduces wiring complexity, installation costs, and the potential for errors. These transmitters are ubiquitous in industries such as oil and gas, water and wastewater treatment, chemical processing, and manufacturing, where accurate pressure monitoring is paramount for safety, efficiency, and product quality.

The core principle behind a two-wire system is that the transmitter draws its operating power directly from the signal loop. When pressure is applied, the transmitter converts this physical measurement into a proportional electrical signal, typically a 4-20 mA current output. This current signal is then superimposed onto the DC power supplied to the transmitter. Therefore, the same two wires that power the device are also used to transmit the pressure information. This is incredibly efficient because a single pair of conductors can perform two essential functions. Here's a breakdown of the key elements involved:

- Power Source: A regulated DC power supply (often 24V DC) is required.

- Pressure Transmitter: The device that senses pressure and converts it to an electrical signal.

- Receiving Device: This could be a PLC (Programmable Logic Controller), DCS (Distributed Control System), a digital indicator, or a recorder. This device interprets the 4-20 mA signal.

- Wiring: A single pair of insulated wires connects all components in series.

The beauty of the 2 Wire Pressure Transmitter Wiring Diagram lies in its simplicity and robustness. The 4-20 mA current loop is inherently less susceptible to electrical noise and voltage drops over long distances compared to voltage-based signals. This makes it a reliable choice for harsh industrial environments. When troubleshooting or installing, understanding this basic wiring configuration is the first step. The typical connection involves connecting the positive (+) terminal of the power supply to one wire, which then goes to the positive terminal of the transmitter. The negative (-) terminal of the transmitter is connected to the other wire, which then returns to the negative terminal of the power supply and also connects to the input of the receiving device.

| Component | Connection Point |

|---|---|

| DC Power Supply (+) | Wire 1 -> Transmitter (+) |

| Pressure Transmitter (-) | Wire 2 -> Receiving Device Input |

| Receiving Device Input (-) | Wire 2 -> DC Power Supply (-) |

For anyone involved in the setup or maintenance of industrial measurement systems, a thorough understanding of the 2 Wire Pressure Transmitter Wiring Diagram is essential. It's the bedrock upon which many sophisticated automation processes are built. To gain further clarity and detailed practical examples, please refer to the comprehensive resources available in the following section.